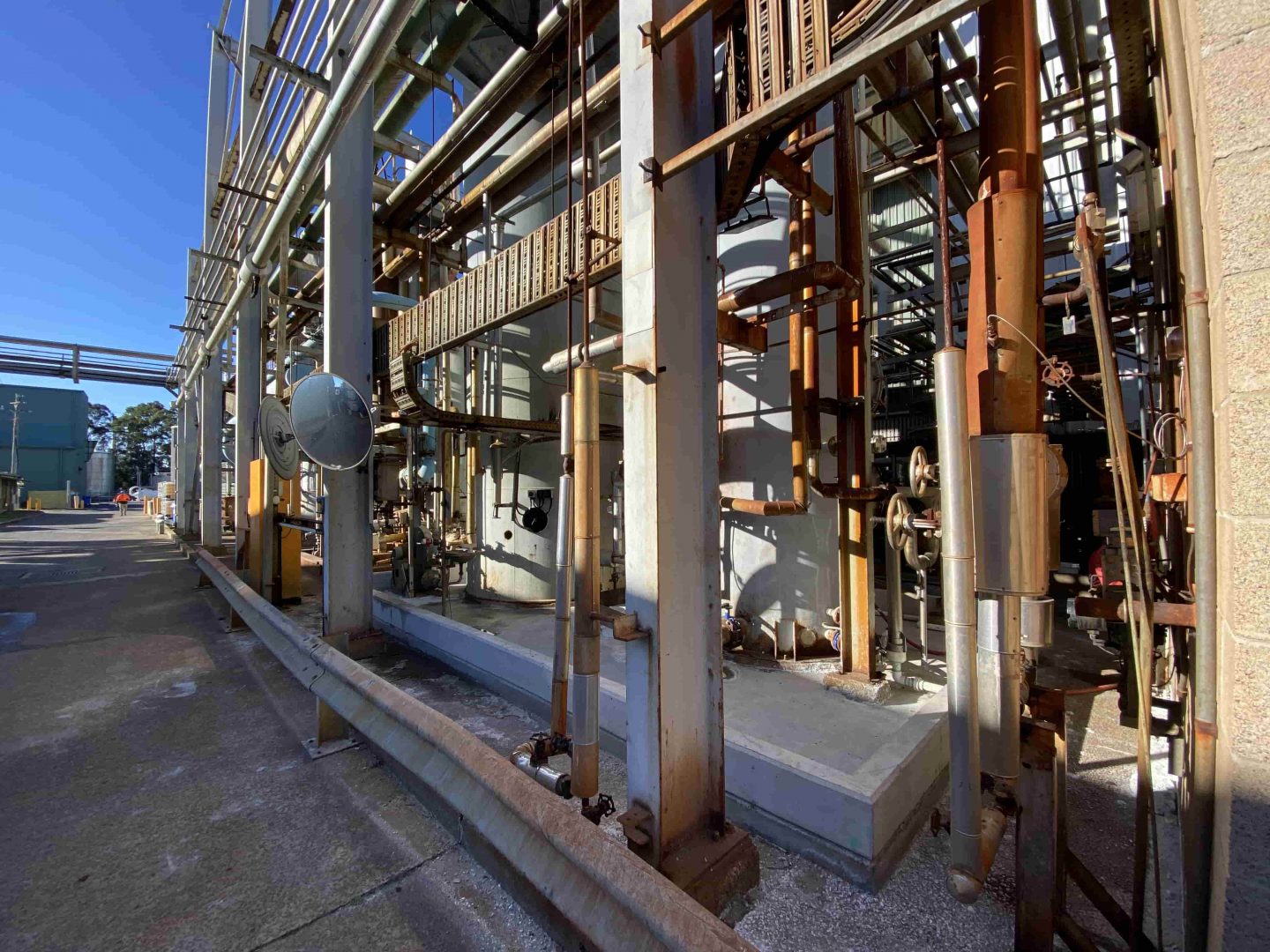

Chemical Plant Remediation in Wetherill Park

Project Details

- Client Albright & Wilson

- Location Wetherill Park

- Duration 4 weeks

Albright & Wilson is a leading manufacturer of phosphates and surfactants in the household, mining & agriculture, industrial and food & beverage industries. They have been servicing the Australian chemical industry with phosphates since 1939 and surfactants since 1958, and maintain a strong reputation in the market for quality goods and services.

The Issues and Their Causes

After continuous operation for many years, as well as being subject to a tough chemical environment, A&W’s Wetherill Park plant had developed some age related issues requiring remedial works. In addition to chemical and mechanical overhauls that fell outside PRR’s remediation services, the following issues were found:

Deteriorating effluent adjustment tank containment slab. Used to adjust the pH of effluent prior to drainage, the slab surrounding the tank had been badly damaged over several years of operation in a high chemical environment.

Deteriorating and damaged storage area concrete bunds. Part of A&W’s storage consisted of stacked ICB’s in a bunded area. Like the adjustment tank, the slab had been subject to a tough environment, sustaining damage from both chemicals and impact from machinery such as forklifts.

Aging driveways and walkways. Some of these had cracked and sunk due to use and age, as well as being worn down by the elements.

Corroded structural steel. The acidic environment saw rust begin to impregnate structural members.

There were extra considerations not found on standard construction and remedial sites. The chemical environment demanded a higher level of awareness from outside workers. Furthermore, part of the plant contained a flammable area. This meant anything electrical or spark inducing had to remain outside.

In April of this year Perfect Remediation and Refurbishment was awarded the contract, with PRR GM Tom Matanovic beginning works in May.

The Repairs

Deteriorating effluent adjustment tank containment slab.

The tank was temporarily decommissioned and the existing slab cleaned. It was formed up and reinforced, and a new topping slab was poured. A floating grate was incorporated into the topping slab and is now a permanent fixture.

Construction of New Containment Areas.

A new bunded area was constructed in line with the existing design: low profile concrete walls surrounding a slab.

Deteriorating and damaged storage area concrete bunds.

Many of the existing concrete bunding were deemed unserviceable. Reinforcing and formwork was installed, and new concrete bunds were poured. The final product was rendered and caulked.

Structural steel reinforcing was installed in damaged areas where repair was not feasible.

Concrete wheel stops were installed to prevent future damage of recently repaired bunds.

Aging driveways and walkways.

How did we fix these?

Perfect Remediation carried out ongoing patch repairs within the facility ensuring safe working surfaces for the plant workers. Patches were completed by utilising rapid set concrete repair mortar material.

The facility will continue to have additional repair works to the main driveway and walkway ideas which will be completed by the Perfect Remediation team.

Corroded structural steel.

Tanks and pipes were braced & temporary walkway props installed to make way for newly designed structural steel walkway supports.

In Conclusion.

All works were completed within the operational facility meeting the strict A&W safety standards and daily pre-start requirements, new works fulfilling the upgrading requirements as well as being aesthetically pleasing.